Prince Fastener:How to Choose Self-tapping Screws for Home Decoration

Different self-tapping screws are used for fixing different building materials in home decoration. There are many kinds of them, and most decorators and owners do not know how to choose suitable self-tapping screws. Although this is a small problem, it is a big problem.

Let’s first look at what self-tapping screws are, and then elaborate on the usage scenarios and methods of each self-tapping screw.

What is a self-tapping screw?

Self-tapping screw: Literally speaking, it is a screw that can be drilled into an object without drilling a hole. It is widely used in different building materials such as wood, iron, steel, aluminum alloy, and plastic. It has both the function of opening and connecting.

For example, we generally call wood screws for connecting wood; a special self-tapping screw for threaded metal holes is called self drilling screw. The intuitive difference is that the head of the self-tapping screw is sharp, while the ordinary screw is basically flat, and the thickness of the screw is the same. Self-tapping screws are generally non-metallic or softer metals.

Types of self-tapping screws:

1. Wood screws

2. Self drilling screw

3. Self-tapping screws

4. Drywall screws

The purpose and use of self-tapping screws:

Since there are too many self-tapping screws on the market, the principle of personal use is cost-effectiveness. The following link is a reference for understanding these screws. The choice of screws should be customized according to your own usage scenarios.

Wood screws:

As the name suggests, it is a screw used to fix wood, and it is a commonly used variety in decoration, woodworking and DIY. High hardness after heat treatment, the thread design of wood screws is relatively deep,fastener suppliers, which is used to connect wood.

Simple and quick to use, screw directly into the wood with an electric drill. However, it is strongly recommended that a guide hole is opened for wood screws above 4mm, and then screwed in. If the diameter is less than 4mm, screw it directly into the wood, and guide the drill bit 1-2mm smaller than the screwed-in screw. Choose it according to the hardness of the wood. For example, use 2mm for softwood and 1mm for hardwood.

Usually, some of the wood screws we buy are very soft. When the electric drill is used, it is either broken or the head is scratched. These screws are generally not heat-treated and have poor hardness. Some of them are overheated and the neck is fragile and easily broken. Almost, there is the poor material itself.

Good wood screws are generally heat treated, the drill bit is not easy to break the head, and it also has a certain toughness, and the neck is not easy to be brittle.

Self drilling screws:

The feature of the self drilling screw is that the tip is in the shape of a drill bit, which looks a bit like a dovetail, also known as a dovetail screw, which is mainly used for fixing thin plates. Cannot be used for metal-to-metal bonding. Such as the fixation of color steel, the connection of thin steel plates and wooden boards. The hardness of the self drilling screw is higher than that of the wood screw, and it can directly drill, tap and lock on the thin plate without auxiliary processing, which saves a lot of time.

There are two types of drill head screws, one is countersunk head, the other is hexagonal head, the countersunk head screw uses a cross drill bit, the wood block is on top, basically use this, it is more beautiful; the hexagonal head uses a sleeve, the connection of metal sheets Hexagons are generally used.

Self-tapping screw:

Self-tapping screws are the free translation of English self-tapping screws. They are characterized by shallow threads and are mainly used for the connection of thin metal plates. Plates that are thinner than drill-tail screws have less hardness than drill-tail screws, such as thin iron sheets, copper sheets, aluminum Connections between metals such as alloys. There are two commonly used countersunk heads and pan heads. The countersunk head is for aesthetics, while the pan head is more stable, and most of them are blue and zinc. Because it is used for metal connection, although the thread is shallow, it needs a balance between hardness and toughness, after all, it is hard.

The screws are divided into countersunk head self-tapping screws, triangle teeth self-tapping screws, triangle teeth screws, wallboard screws, hand screws, wood screws, machine wood screws, machine screws, fiberboard screws, self-tapping screws, non-standard screws, etc., among which Countersunk head self-tapping screws include DIN7972, DIN7982, etc. Then why is it named “countersunk head tapping screw”, and what are the characteristics of the material?

What is a countersunk head self-tapping screw? What does the front “countersunk head” mean?

Countersunk head means that the screw head will not be higher than the fixed surface after the screw is tightened (meaning sinking inside!), self-tapping is to open a small hole first without tapping the screw to fix it!

What is the difference between fiberboard nails and cross countersunk self-tapping screws?

From the design and application of countersunk head self-tapping screws, it can be known that self-tapping screws such as countersunk head self-tapping screws are not the best choice for application on wood compared with fiberboard nails, for the following two reasons.

1: Self-tapping screws such as countersunk head tapping screws have shallow threads and cannot provide sufficient tension when used in wood such as particleboard. Iron objects have higher hardness, so they can provide enough tension.

2: When the screw is screwed in, the connected part will form a threaded hole. The shallower the thread, the smaller the deformation. When a hard object like iron has enough tension, the smaller the deformation, the easier it is to screw in.

3: Self-tapping screws are mostly used for the connection between thin metal plates (steel plates, saw plates, etc.). When connecting, first make a threaded bottom hole for the connected piece, and then screw the self-tapping screw into the threaded bottom hole of the connected piece. Since the threaded surface of the self-tapping screw has high hardness (≥45HRC), the internal thread can be tapped in the threaded bottom hole of the connected piece to form a connection.

The material of countersunk head self-tapping screw is generally carburized steel, and the surface hardness of the material after heat treatment is not less than 45HRC. Compared with the thread of ordinary screws, when the major diameter is the same, the pitch is larger and the minor diameter is slightly smaller, which has been standardized.

Self-tapping screw materials can be divided into two types: carbon steel and stainless steel. Among them, carbon steel materials are usually 1022 medium carbon steel. Usually used in doors and windows, iron. Its head is the bearing surface formed by the enlarged shape at one end. For thread forming and thread cutting self-tapping screws (self-tapping screws), flat countersunk (Flat? Countersunk), flat countersunk (Oval Countersunk) , Pan head (Pan), Hex and Hex washer head (Hex and Hex washer Head) are the most important, these five head types account for almost 90% of all self-tapping screws. Consider this.

The other five other types are Flat Undercut, Flat Trim, Oval Undercut, Oval Trim and Fillister ) is to compare the secondary head type, and the fragrant top is countersunk. The selection of the head type of the thread rolled into a self-tapping screw (self-tapping screw) is the same as the above, and the main consideration is mushroom head (Truss), round head (Round) and 100 degree flat. The top countersunk head is not used in the new design, and the function of the cover can be replaced by other head types. The pan head can replace the mushroom head and the round head. , Hexagon head and Hexagon washer head five kinds.

Screws are indispensable industrial necessities in daily life: tiny screws for cameras, glasses, clocks, electronics, etc.; general screws for televisions, electrical products, musical instruments, furniture suppliers, etc.; large screws for engineering, construction, and bridges , nuts; transportation equipment, aircraft, trams, automobiles, etc. are used for large and small screws. Screws have important tasks in industry. As long as there is industry on earth, the function of screws will always be important.

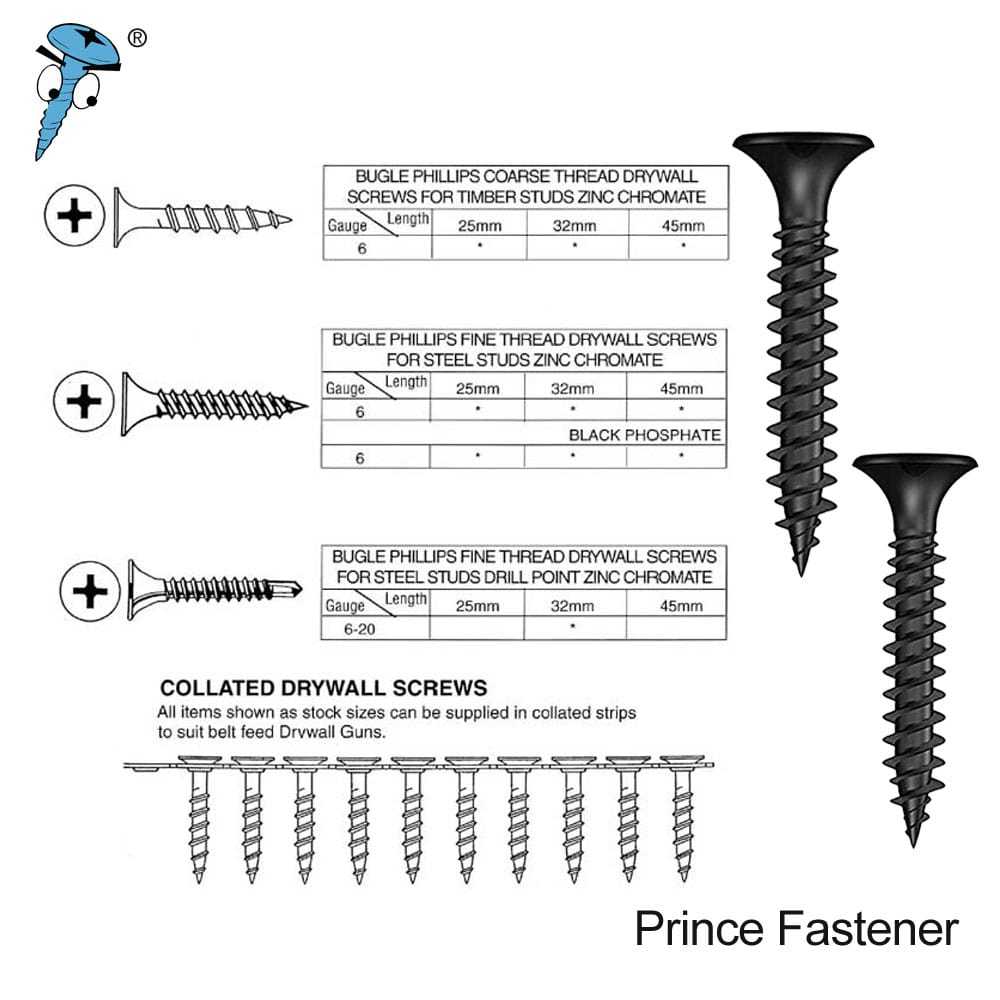

Drywall screws:

Commonly known as chipboard screw, translated from English Drywall Screw, the biggest feature is the horn head, divided into double-line fine-tooth drywall screw and single-line thick-tooth drywall screw, mainly used for gypsum board and wood keel and gypsum board and light steel keel. connect.

Drywall screws are divided into black and blue and white in terms of color. The drywall screws after phosphating are black, which is what most of us use, while blue and white zinc are rarely used. The reason is that drywall nails are mostly used indoors, and black phosphating has a certain lubricity and fast attack speed; while blue and white zinc is better in rust prevention.

There are many people who use drywall nails to connect plates in China. It is recommended to use wood screws. The biggest difference between them is the thread depth and the distance between the threads. The wood screws are deeper and the thread spacing is larger.

What is the difference between drywall screws and self-tapping screws

The differences between drywall screws and self-tapping screws are:

1. Different uses: Drywall nails are mainly used for the installation of various gypsum boards, lightweight partition walls and ceiling series. Self-tapping screws are used for non-metal or softer metals without drilling and tapping.

2. Different features: The biggest feature of drywall nails is the shape of the horn head. The characteristics of self-tapping screws are that they have low screw-in torque and high locking performance. They have better working performance than ordinary self-tapping screws and can be used instead of machine screws.

3. The classification is different: drywall screws are divided into two types: double-line fine-tooth dry-wall screws and single-line coarse-tooth dry-wall screws. Self-tapping screws can be divided into round head self-tapping screws, flat head (ie countersunk head) self-tapping screws, top column head self-tapping screws, dome wide-side head self-tapping screws, and large round head (ie, large flat head) self-tapping screws according to different heads. Tapping screws, hexagonal socket head self-tapping screws, hexagonal socket head self-tapping screws, hexagonal socket head self-tapping screws, etc.

According to the groove type, there are four types of self-tapping screws with one-word groove head type (also called slotting), cross groove head type self-tapping screws, eleven-shaped composite groove head type self-tapping screws, and rice-shaped groove head type self-tapping screws. According to the standard, it can be divided into national standard (GB) self-tapping screws, German standard (DIN) self-tapping screws, American standard (ANSI) self-tapping screws, and British standard (BS) self-tapping screws.