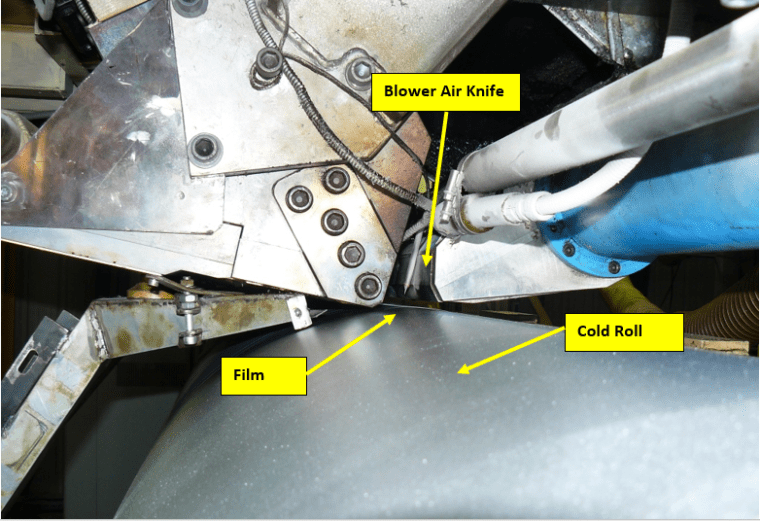

A plastic company produced many kinds of films and sheets. They were having issues with one particular film, an OPS (Polystyrene) film which was 0.012” (300 microns) thick and 30” (762mm) wide. As the material was extruded into a flat sheet, they would run it over a cold roll drum (Reference photo above). The cold drum is a large cylinder that has chilled water running through it. To keep the sheet on the surface of the cold drum, they used a blower air knife system. With the blower air knife, they were having variation in thickness as well as stretch marks. They heard about the EXAIR Super Air Knife, and they wanted me to do a comparison. I was glad to compare the EXAIR 110230 30” Super Air Knife Kit to their blower-type air knife system.

- “Stretch” marks on the plastic film:

- Blower System – Hot air is generated by the blower system. When the hot air hits the cool surface, it would cause an uneven hardening of the material, causing stretch marks.

- Super Air Knife – It has a 40:1 amplification ratio. That means that 40 parts of the ambient air is entrained with 1 part of compressed air. Being that the ambient air is much cooler than the hot air from the blower system, it actually aides in cooling. There is no thermal shock to the sheet material, and hardening is consistent and faster.

- An even force across the plastic film:

- Blower System – Their design had one 4” (102mm) line feeding into the side of the blower air knife. This would cause two issues for an even force. As the velocity of the air hits the opposite side of the knife, the closed end, a turbulent air flow is developed. Also, there would be a slight negative pressures at the entrance caused by the velocity of the air entering. This chaotic turbulent flow caused an uneven force on the surface of the film.

- Super Air Knife – The flow that is delivered from the Super Air Knife is laminar. This means that the force and velocity is consistent across the entire length, even on the target. With this even force, the film was held evenly and securely on the cold drum. With a filter, shim set, and regulator that is included in the kit, the force can be easily adjusted to the perfect requirement.

- Maintenance requirements:

- Blower System – Preventative maintenance is a requirement. The blower filters have to be changed regularly, and the mechanical and electrical components have to be checked. This requires downtime to the system. In addition to this, blower motors are mechanical devices. The bearings will wear and the motor will fail. If a mechanical failure does occur, the downtime can cost days of operation. These items should be checked quarterly as a PM which increases the cost of ownership.

- Super Air Knife – No moving parts to wear out. The only maintenance would be to change the compressed air filter once a year. There is no worry about catastrophic failure.

- Noise levels:

- Blower System – With the blower motor and turbulent air flow, the system makes a lot of noise. They have a sound level near 93 dBA which would need PPE for nearby operators.

- Super Air Knife – These units are very quiet. At a pressure of 100 PSIG (6.9 bar), the sound level is only 72 dBA. No additional cost for PPE or the constant nagging disturbance of loud noises.

- Compact Design:

- Blower System – The foot print of the blower is large and it takes up much floor space. The 4” (102mm) duct has to be ran to an oversized air knife (Reference photo below). With the turbulent flow, the blower air knife has to be mounted close to the film surface. So, it can make it difficult to optimize the placement.

- Super Air Knife – With the compact design, the Super Air Knife has a large force in a small package. The model 110230 Super Air Knife has a footprint of 1 ¾” X 1 ½” X 30” long (44 X 38 X 762mm respectively) with only two ¼” NPT compressed air lines feeding it. The force measurement is the same from 3” (76mm) to 12” (305mm) away from the surface; giving flexibility in placement.

When it comes to using the EXAIR Super Air Knives, it has many benefits over the blower-type air knives. We can even include the initial purchase price in which the Super Air Knife would be about 1/10 the cost, and the company was able to increase production with a cooler blowing device. They were delighted to remove the large blower-type system and replace it with a simple Super Air Knife. If you would like to discuss the advantages of the Super Air Knife against a blower system, an EXAIR Application Engineer will be happy to assist.

John Ball

Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb