Valves are pivotal components across numerous industries, responsible for controlling the flow and pressure of fluids such as liquids and gases. Whether in household plumbing or sophisticated industrial systems, valves ensure operational safety and regulate system performance. With a wide variety of valves available, each is designed to serve specific applications, including construction zones where geogrids are utilized to stabilize structures.

What is the basic function of a valve?

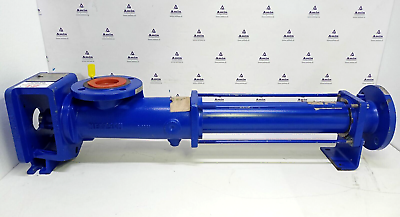

A valve is a mechanical device that regulates, directs, or shuts off the flow of a fluid. It can be manually or automatically operated. Valves alter the fluid’s flow path by opening or closing, which affects the speed and pressure of the fluid moving through a system. They are indispensable in systems ranging from simple household plumbing to complex industrial applications.

What types of valves exist?

There are many types of valves, each designed for specific purposes. The most common types include:

- Gate valves: Used to isolate or control fluid flow.

- Ball valves: Known for their quick and easy control via a quarter-turn motion.

- Butterfly valves: Ideal for space-saving applications that require precise flow control.

- Check valves: Prevent backflow in fluid systems.

- Globe valves: Perfect for regulating flow in high-pressure environments.

Choosing the right valve depends on the fluid’s properties and the application’s requirements.

How do valves integrate into construction projects?

In construction and civil engineering, valves are essential in hydraulic systems, water management, and drainage operations. When paired with geogrids, which reinforce and stabilize soil, valves can regulate water flow and prevent erosion in retaining walls or roadways. This partnership ensures the longevity and stability of critical infrastructure projects.

What are the best practices for valve maintenance?

Valves should be maintained regularly to ensure long-term efficiency. This includes inspecting for wear, replacing gaskets and seals, and ensuring that moving parts remain lubricated. Proper maintenance is crucial in preventing system failures in complex environments, such as construction sites where geogrids and valves work together to protect structures from water damage.