In systems, it is important to understand the type of medium that is being used. For most EXAIR products, this will be compressed air. As the air compressor draws in ambient air, it also brings in dust, contamination, and moisture into the system. If untreated, the pneumatic system will have to contend with these foreign “invaders” that will affect the performance of your pneumatic devices. One of the most common problems is water.

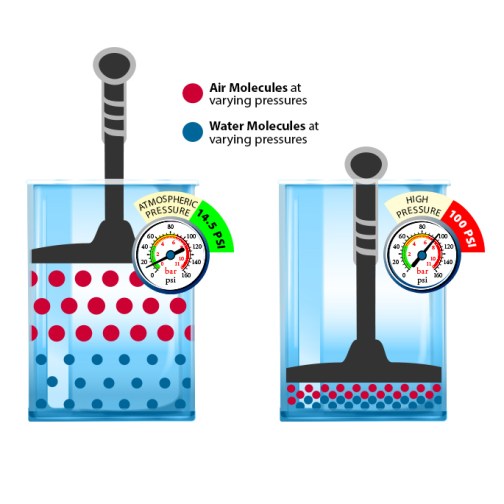

Water enters the compressed air system from the water vapor already present in the ambient air, which is referred to as the dew point or relative humidity. When you take ambient air and compress it, the amount of “elbow room” for the water vapor decreases. This causes the water vapor to condense and create liquid water. It would be similar to a water-soaked sponge. As you compress it with your hands, the sponge will not be able to hold on to the water. Similarly, as the air is compressed, water will start to form and fall out into the compressed air system. Water is a by-product of a compressed air system.

The definition for determining if liquid water is present in your system is called the pressure dew point. Dew point is the temperature at which water vapor will condense and form water droplets. If the dew point temperature and the air temperature are equal, then the air is considered 100% saturated (water vapor will start to condense to form water droplets). In compressed air systems, air dryers are used to reduce the dew point temperature. This means that unless the ambient temperature falls below the dew point temperature, water vapor will not condense into a liquid state.

There are two major types of compressed air dryers; refrigerated and desiccant. The refrigerated air dryers are the most common, and the dew point is measured at about 39oF (4oC). So, unless the air temperature gets close to freezing, i.e., the piping system that goes outside in cold weather, water should not be present. Desiccant air dryers can achieve dew points as low as -40oF (-40oC). This compressed air is very dry and can be used for medical systems, food and beverage processing, and instrument air. The reason is that bacteria cannot survive in compressed air that is that dry. The other types are dewpoint reducing systems, which include membrane and deliquescent dryers.

For most pneumatic devices, a Filter Separator with an auto-drain should be used as a minimum amount of protection. Even with systems that have compressed air dryers as described above, they are mechanical devices. So, failures can occur. You should review your compressed air system to ensure that your pneumatic system, including EXAIR products, is operating at peak efficiency. This will include your supply system, compressed air leaks, and blow-off devices.

Moisture-laden compressed air can cause issues such as increased wear on the pneumatic tools, the formation of rust in piping and equipment, quality defects in painting processes, and frozen pipes in colder climates. Regardless of what products you’re using at the point-of-use, a compressed air dryer is undoubtedly a critical component of the compressed air system. Providing clean, dry air to EXAIR Products or other pneumatic devices will help to extend the life of your equipment. If you wish to discuss more about your compressed air system or how EXAIR can provide a more efficient way to use that compressed air, an Application Engineer will be happy to assist you.

John Ball

International Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb