Pressure drops, incorrect plumbing, undersized piping, insufficient flow; if you hear these terms from tech support of your point of use compressed air products or from your maintenance staff when explaining why a process isn’t working then you may be a victim of improper compressed air piping selection.

Often time this is due to a continued expansion of an existing system that was designed around a decade old plan. It could also come from a simple misunderstanding of what size of piping is needed and so to save some costs, smaller was used. Nonetheless, if you can understand a small number of variables and what your system is going to be used for, you can ensure the correct piping is used. The variables that you will want to consider when selecting a piping size that will suit your need and give the ability to expand if needed are shown below.

- Minimum Operating Pressure Allowed (psig) – Lowest pressure permitted by any demand side point of use product.

- System Pressure (psig) – Safe operating pressure that will account for pressure drops.

- Flow Rate (SCFM) of demand side (products needing the supplied compressed air)

- Total Length of Piping System (feet)

- Piping Cost ($)

- Installation Cost ($)

- Operational Hours ( hr.)

- Electical Costs ($/kwh)

- Project Life (years) – Is there a planned expansion?

An equation can be used to calculate the diameter of pipe required for a known flow rate and allowable pressure drop. The equation is shown below.

A = (144 x Q x Pa) / (V x 60 x (Pd + Pa)

Where:

A = Cross-Sectional are of the pipe bore. (sq. in.).

Q = Flow rate (cubic ft. / min of free air)

Pa = Prevailing atmospheric absolute pressure (psia)

Pd = Compressor discharge gauge pressure (psig)

V = Design pipe velocity ( ft/sec)

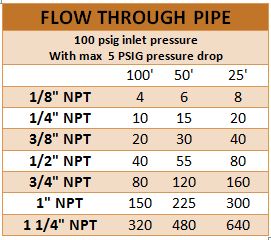

If all of these variables are not known, there are also reference charts which will eliminate the variables needed to total flow rate required for the system, as well as the total length of the piping. The chart shown below was taken from EXAIR’s Knowledge Base.

Once the piping size is selected to meet the needs of the system the future potential of expansion should be taken into account and anticipated for. If no expansion is planned, simply take your length of pipe and start looking at your cost per foot and installation costs. If expansions are planned and known, consider supplying the equipment now and accounting for it if the additional capital expenditure is acceptable at this point.

The benefits to having properly sized compressed air lines for the entire facility and for the long-term expansion goals makes life easier. When production is increased, or when new machinery is added there is not a need to re-engineer the entire system in order to get enough capacity to that last machine. If the main compressed air system is undersized then optimal performance for the facility will never be achieved. By not taking the above variables into consideration or just using what is cheapest is simply setting the system up for failure and inefficiencies. All of these considerations lead to an optimized compressed air system which leads to a sustainable utility.

Brian Farno

Application Engineer

BrianFarno@EXAIR.com

@EXAIR_BF