In today’s competitive industrial landscape, cost efficiency is paramount. One of the most effective ways to achieve this is by utilizing progressive cavity OEM spare parts. These components are specifically designed to enhance the performance and longevity of your equipment while reducing operational costs. In this article, we will explore the benefits of using progressive cavity OEM spare parts, ways to save money, and best practices for maintenance.

Understanding Progressive Cavity Pumps

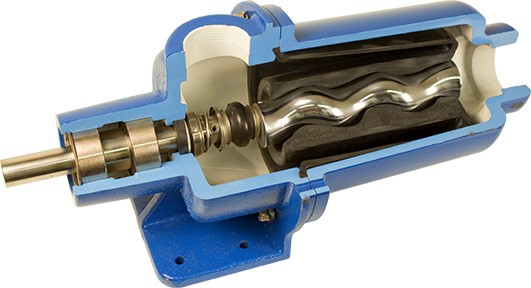

Progressive cavity pumps are a type of positive displacement pump that moves fluids through a rotating mechanism. They are known for their ability to handle viscous fluids and maintain a steady flow, making them ideal for various applications in industries such as wastewater treatment, food processing, and oil extraction. The efficiency of these pumps largely depends on the quality of their parts.

Advantages of Using OEM Spare Parts

When it comes to replacing parts, the choice often lies between original equipment manufacturer (OEM) parts and generic alternatives. Here are some advantages of choosing OEM spare parts:

- Quality Assurance: OEM parts are manufactured to the same specifications as the original components, ensuring reliability and performance.

- Compatibility: These parts are designed to fit perfectly with your existing equipment, reducing the risk of malfunctions.

- Warranty Protection: Using OEM parts helps maintain the warranty of your equipment, offering peace of mind and financial protection.

- Longevity: OEM spare parts often have a longer lifespan compared to generic parts, resulting in fewer replacements over time.

Strategies to Save Money with OEM Spare Parts

While OEM spare parts may seem more expensive upfront, they can lead to significant savings in the long run. Here are some strategies to optimize your spending:

1. Preventive Maintenance

Investing in preventive maintenance can drastically reduce the need for frequent repairs and replacements. By regularly inspecting and maintaining your equipment, you can identify potential issues before they escalate, extending the life of your progressive cavity pumps and their parts.

2. Bulk Purchasing

If your operations require a consistent supply of spare parts, consider bulk purchasing. Buying parts in larger quantities often comes with discounts, helping you save money over time. Additionally, having spare parts on hand can minimize downtime during repairs.

3. Establish Relationships with Suppliers

Building strong relationships with your suppliers can lead to better pricing and exclusive deals. Regular communication can also help you stay informed about upcoming sales or promotions, allowing you to purchase parts at lower costs.

4. Optimize Inventory Management

Effective inventory management can help you avoid overstocking or running out of essential parts. Utilize inventory management software to track usage patterns and predict future needs, ensuring that you only order what you require.

5. Train Your Staff

Ensuring that your staff is well-trained in the use and maintenance of progressive cavity pumps can prevent mishandling and unnecessary wear and tear. A knowledgeable team can also perform basic maintenance tasks, reducing reliance on external services.

Best Practices for Maintaining Progressive Cavity Pumps

To ensure that your progressive cavity pumps operate efficiently and have a long lifespan, follow these best practices:

- Regular Inspections: Schedule routine inspections to check for leaks, wear, and other potential issues.

- Lubrication: Ensure that moving parts are adequately lubricated to minimize friction and wear.

- Monitor Performance: Keep an eye on the pump’s performance, including flow rates and pressure levels. Any significant changes may indicate a need for maintenance or replacement parts.

- Cleanliness: Maintain a clean working environment to prevent contaminants from entering the pump system.

- Documentation: Keep detailed records of maintenance activities and part replacements to help track performance trends and plan for future needs.

Conclusion

Using progressive cavity OEM spare parts is a smart investment for any business looking to enhance operational efficiency and reduce costs. By understanding the advantages of these parts and implementing effective strategies for maintenance and procurement, you can significantly lower your long-term expenses. Prioritizing quality and reliability will not only save you money but also ensure that your equipment operates at peak performance for years to come.