I like a good sharp table saw blade as much as any woodworker.

But I also don’t want to overspend on a blade, also just like any woodworker.

So what I did was come up with a list of saw blades that are useful in most woodshops, and depending on your needs and your budget, you can determine which ones are worth spending money on, and which ones not so much.

But before we dive into all that, I’d like to explain some fundamentals so we’re both on the same page with why this does this, and why that does that, etc.

Table Saw Blades 101 – An Intro To The Blade and Its Teeth

First lets define a few key terms and acronyms:

Kerf – The width of the blade tooth. Full kerf is 1/8″, thin kerf is 3/32″.

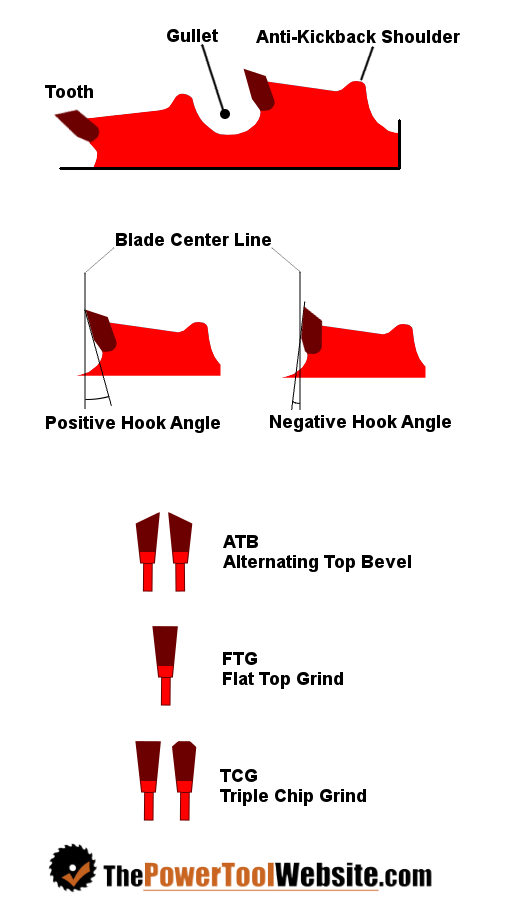

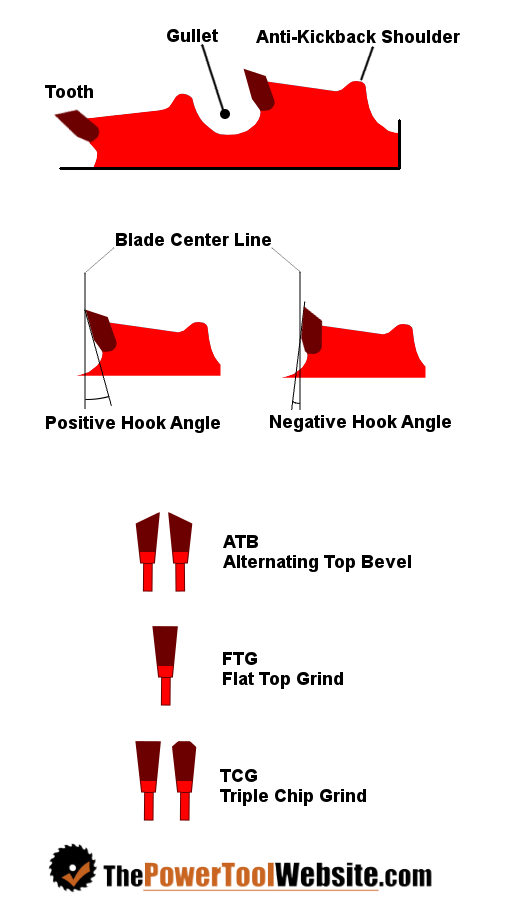

Gullet – this is the curved cutaway part of the blade between the teeth.

Anti-Kickback Shoulder – This is a non-cutting part of the blade that protrudes out behind a tooth.

ATB – Alternate Top Bevel

FTG – Flat Top Grind

TCG – Triple Chip Grind

Hook Angle – The angle in which the tooth leans forward or backward. Negative is leaning back. Positive hook angle is more aggressive and leans forward into the cut.

Table saw blades use carbide teeth, as this material is harder than steel and holds a sharp edge longer. However, the carbide is more brittle, so take care not to damagine the teeth when changing blades, or storing them.

Now let’s discuss the purposes of the different saw blade features and types.

Thin Kerf Blades

Thin kerf blades are usually rip blades that are made thin so a lesser-powered table saw (like a contractor 110v model) can handle thicker, denser wood. The thinner kerf requires less power to push through the cut, so the motor will bog down less.

Another reason you may want to use a thin kerf blade is to leave a thinner kerf cut in the wood, which results in less material being removed from the board.

So that all sounds pretty good, right? Why not just use thin-kerf blades all the time?

The reason we don’t use them for everything is because they have a limited (if any at all) resharpening life.

Also, the thinner body of the blade is more prone to vibration, which can reduce the quality of the finish from the cut.

On the flip side, a full kerf blade is typically made with bulky enough teeth that they can be resharpened multiple times before going in the trash.

And its thickness helps with stability to reduce vibration in the blade while cutting.

The Gullet

This is a feature to help remove waste material.

With the tooth cutting away material from the board, it builds up quick through the cut.

The gullet is just a relief that’s there to give the waste material somewhere to go while that tooth is passing through the wood.

Shoulders

The anti-kickback shoulders are common with rip blades.

Because of the faster feed rate these blades support, the shoulder is added to reduce the chance of a kickback.

Do they really help? I can’t answer that. When it comes to kickback, don’t trust these shoulders to do it all. Use your splitter or riving knife, and some good ‘ol common sense when you’re cutting.

Which Table Saw Blades Should You Get – And Why

Don’t let the blade manufacturers sell you on high dollar rip blades, unless you’re seriously running a production line and need to rip a lot of boards down fast.

Use the following recommendations to determine for yourself which kinds of blades are worth spending extra on, which ones are ok to cheap out on, and which ones can be ignored altogether.

1 – Combination or General Purpose

“90 percent of the time, it works every time”

If you’re gonna spend money on a blade, spend it on a high-quality Combination or General Purpose blade. This handles most the work, for most woodworkers.

A “Combination Blade” has groups of 5 teeth. 4 ATB teeth, and one trailing FTG tooth, followed by a large gullet. The ATBS make for a cleaner cut, and the FTG tooth with the large gullet takes on the role of a rip tooth.

A “General Purpose” or “All Purpose” blade is going to be your 40 tooth blade with ATB teeth only.

These 2 table saw blade styles are designed to handle rip cuts and crosscuts, while leaving a mostly-smooth finished surface, that will require a bit of sanding.

It’s a compromise between a fast cutting rip blade, and a fine cutting crosscut blade.

It handles most cuts just fine, and saves time as you don’t have to change out the blade for every other cut.

I’ve got myself a Freud Combination blade and I love it.

2 – Stacked Dado Set

Dados? Rabbets? If you haven’t had to make these groove cuts in your projects yet, you probably will soon. Read about Dados and Rabbets here.

If you’ve got several to cut in a single project, it saves time to use a stacked dado blade set, instead of your regular blade.

These will probably come with ATB blades for the outer blades, and FTG for the inner “Chipper” blades. This combination makes for easier and faster cuts, while leaving a nice, crisp corner at the dado edges.

I didn’t spend too much on mine, as I don’t use it that often. I’ve got the Irwin Marples which works pretty well. My only complaint is the very thin shims can drop down into the arbor threads before you tighten the arbor nut.

Then when you tighten the nut, it works fine but you end up finding out you crimped the edge of the shim when it was tightened. Not a big deal though.

3 – Crosscut Blade

If you’ve got a miter saw, you need to keep a crosscut blade in it. A general purpose, combination, or rip blade serves no benefit in a miter saw.

A crosscut blade uses a high number of ATB teeth. This makes for a very clean cut across the grain.

For me, my final crosscuts are almost always made on the table saw sled with my Freud Combo blade, so I do not spend much money on my miter saw crosscut blades.

But using a crosscut blade either way (expensive or not), will produce a cleaner crosscut than an equally priced combo or general purpose blade.

4 – FTG Blade

If you’re using your table saw to make dovetails or box joints, I would suggest getting a blade specifically for that.

Your standard ATB blade will not leave a flat surface in your dovetail pin board, while an FTG blade will. This means far less tedious cleanup with a chisel.

Your tail board will not be clean no matter what blade you use, as the blade will be beveled (or the board tilted) when making the cuts.

But save yourself time on the pin board by using a decent FTG toothed crosscut blade, unless you just don’t do these often and then just plan on using a chisel to clean it up.

5 – Plywood & Melamine Table Saw Blades

If you do a lot of work with veneered plywoods or melamine, you may want to invest in a decent plywood blade. These have lots of teeth, ATB style, and a low hook angle to make it even less aggressive.

This configuration produces the least amount of tearout and chipping on these manufactured veneered sheet goods.

So for building a lot of cabinets, I would recommend this style of blade.

However, if you’re just doing the occasional rustic-style cabinet project, or are not overly concerned with having absolutely zero tearout on every cut, then just stick with your combination blade for plywood cuts.

That’s what I do and so far I’ve been happy with the results.

6 – TCG Blade

Finally, if you will be cutting non-ferrous metals, or a lot of really dense product, like MDF, plastic, or laminate, get you one of these blades.

It’s not really going to give you a faster, or a cleaner cut necessarily. What it will do is last longer than any ATB blade making these cuts.

The sharp knife-edges of an ATB tooth dull much quicker in dense material, so using your standard combo blade on lots of plastic or mdf, can get costly in resharpening bills.

Any other specialty cutting?

If you have any other specialty cuts that you will be making on a regular basis, find a blade made for that. These are made so you don’t expedite the dulling process on your main wood-cutting blade.

References:

https://www.woodcraft.com

https://www.rockler.com