The first new car I ever bought was a 1995 Ford Escort Wagon. It got GREAT gas mileage (which was important for my 25 mile one-way commute to the day job), and had ample room to haul my keyboards & amplifier rig (which was just as important to my side hustle as a potential rock star). Since it only had four miles on the odometer – and, it was the first purchase I ever financed over a period of YEARS, I decided to follow the owner’s manual’s maintenance schedule religiously. And it paid off: I got eleven years and just shy of 200,000 miles out of one of the least expensive cars ever made. It was actually still running like a top when I sold it to “upgrade” to a minivan, which suited my needs at the time for a vehicle that fitted the car seats for our little boys (who are now a U.S. Marine and a hippie college student, respectively). I actually followed the maintenance schedule for that minivan too, and got 14 years & almost 180,000 miles out of it, without a major breakdown.

Whether you call it “preventive”, “preventative”, “scheduled”, or “planned” maintenance, there’s an old adage that applies in any case:

“If you don’t plan maintenance, it’ll plan itself without regard to your schedule.”

While following the proverbial “owner’s manual’s maintenance schedule” doesn’t guarantee against catastrophic failures, it’s awfully good insurance against them. For your privately owned vehicles, I encourage you to follow the owner’s guide as best you can. For your compressed air system – from the compressor to the devices it provided compressed to (and everything in between) – there’s likely similar documentation to follow, and for good reason. Consider:

- Air compressor maintenance. Failure to properly maintain a compressor can increase energy consumption by not keeping it operating as efficiently as possible. For example, just like not periodically replacing your car engine’s air filter will impact your gas mileage, failure to do the same for your compressor’s intake air filter will impact its production of compressed air.

- Air leaks are costly. Not only do they waste the money you spent on running the compressor (a leak that’s equivalent to a 1/16″ diameter hole costs you over $700.00 annually – let me know if you want to do the math on that), your system pressure takes a hit too. Pressure drop caused by those leaks (plural because there’s rarely just one) can create what’s known as “false demand”, which costs you money as well: every 2psi increase in compressor discharge pressure makes for a 1% increase in power consumption. So, it’s really important to stay on top of them. Regularly scheduled surveys with an instrument like EXAIR’s Model 9207 Ultrasonic Leak Detector allows you to quickly find – and then fix – those leaks.

- Filters, part 1: I already mentioned the compressor intake filter above, but the rest of the filters in the system need attention from time to time as well. Filter manufacturers typically call for replacing the element in a filter when pressure drop reaches a certain point. I’ve seen published values of 2-5psi for that. Of course, that may not occur at a convenient time to shut down everything downstream of that filter, so lots of folks replace those elements as part of planned maintenance evolutions that require depressurization of that particular part of the system anyway. Dirty filters mean you have to increase their inlet pressure to maintain the same outlet pressure you had when they were clean – and the same 1% increase in power consumption for a 2psi pressure increase applies here too.

- Filters, part 2: most compressed air operated products have small passages that the air has to flow through, and without filtration, those can get clogged with dirt that the intake filter doesn’t catch, solid particulate from compressor ‘wear & tear’, and rust from header pipe corrosion, just to name the “usual suspects”. An argument could be made that installation & upkeep of properly rated Filter Separators at the point of use of these devices is part of those devices’ planned maintenance. In any case, it’s akin to the awfully good insurance against catastrophic failures I mentioned earlier.

Again, many of the components that make up a typical industrial compressed air system will have a manufacturer’s recommended maintenance schedule, but if they don’t, how can you properly plan for it? Monitoring of certain system parameters can be a valuable tool for determining how often some planned maintenance should be performed:

- Power consumption of the compressor. The benefit of measuring & logging this on a regular basis is, if you see sudden changes, you can start looking for what’s causing them. Maybe a bearing or belt is wearing out, some leaks have popped up, or a filter’s clogged. In any case, it’s an indication that SOMETHING needs attention. Large industrial compressors might even have power monitoring in their control scheme. If not, there ARE other parameters you can measure…like:

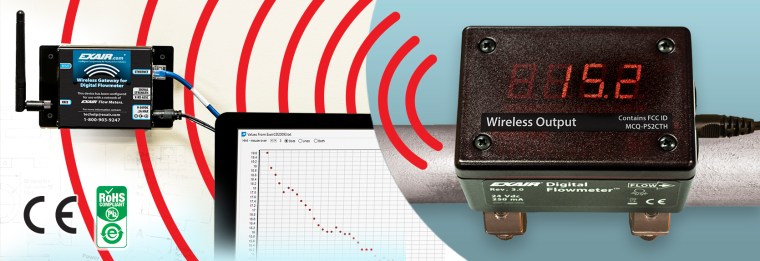

- Pressure and flow. EXAIR’s Pressure Sensing Digital Flowmeters make monitoring these parameters quick and easy. Managing the readings can be done with our USB Data Logger, or you can get it on your computer, via a Zigbee Mesh Gateway, with our Wireless Models.

At EXAIR, we’re committed to helping you get the most out of your compressed air system. If you’d like our help with that, give me a call.

Russ Bowman, CCASS

Application Engineer

Visit us on the Web

Follow me on Twitter

Like us on Facebook

Featured image courtesy of Compressor1 – creative commons license